Fa'amatalaga

Fa'amatalaga o oloa

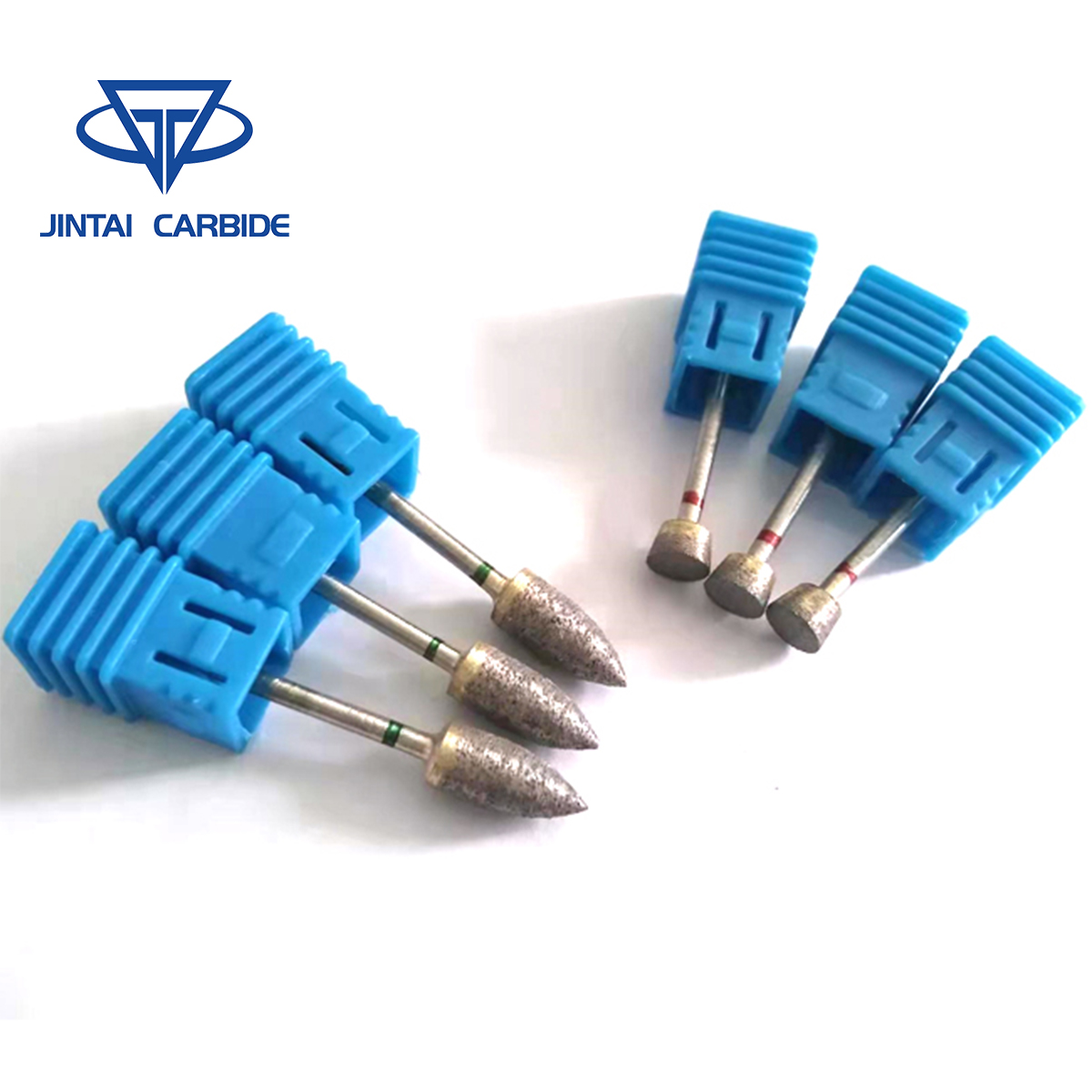

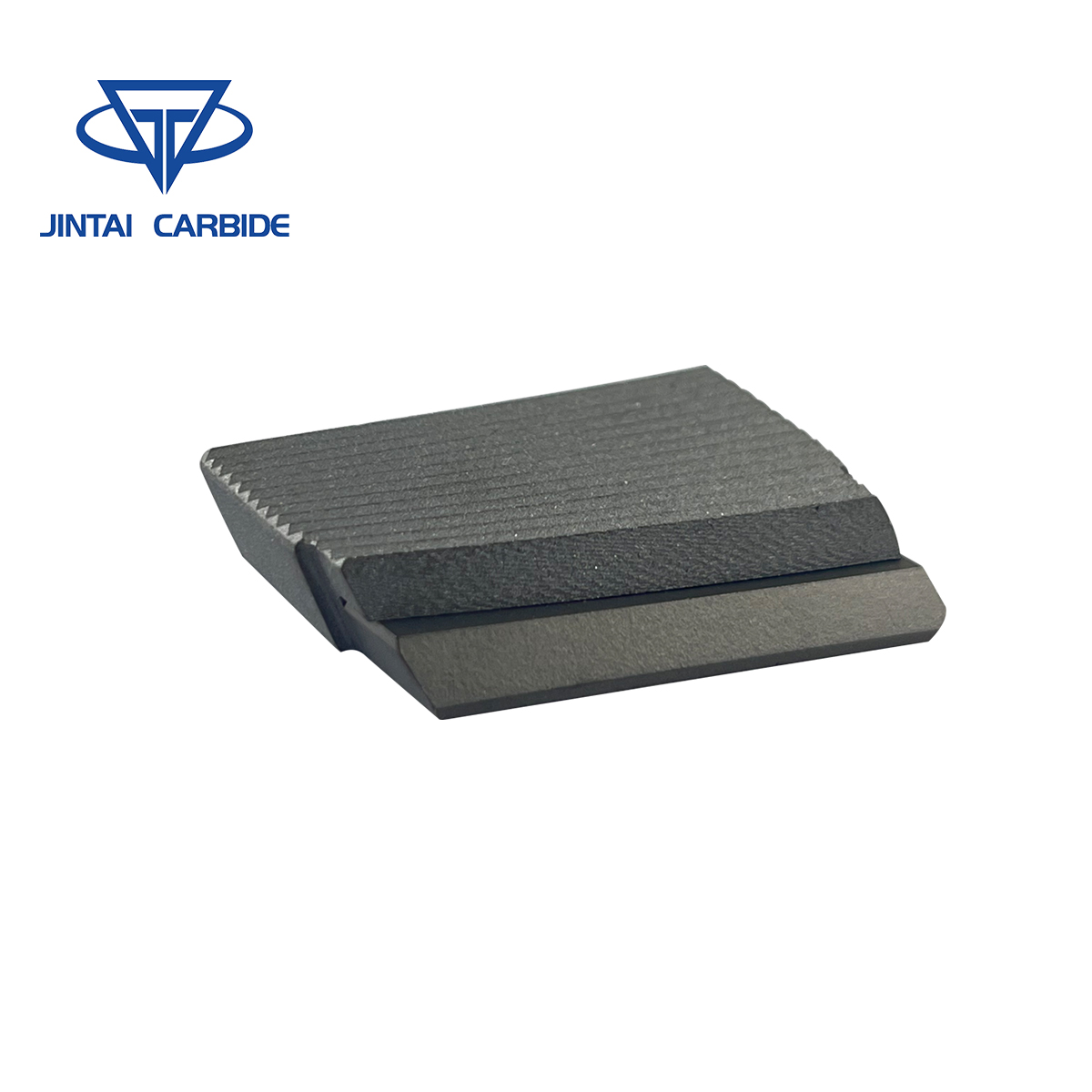

La'au carbide sima e lelei le sa'o, lelei le maa'a, ma le mautu.

E fautuaina le fa'au'u ili, fa'ato'a ma ili.Fa'atinoga lelei mo le tipi saosaoa.E fetaui mo le tipiina o le uamea faʻamaʻa, alumini alumini ma le Titanium alloy.Matou te tu'uina atu fa'aleaganu'u, fa'alatalata- upega, fa'apipi'i fa'asili avanoa i carbide sima - e ta'ua fo'i o Tungsten carbide po'o carbide malo.

Tulaga meafaitino:

1. Meatotino Faaletino:

A) Malosi e sili atu pe tutusa ile 92.8 HRA;

B) Ole mamafa e sili atu pe tutusa ile 14.2 g/cm³;

C) TRS sili atu pe tutusa ma le 4200 N/mm²;

D) Sa'oloto ole vaega ole tulaga ole ETA;

E) Leai se fa'aleagaina e isi mea;

F) Porosity = A00 / B00 / C00 ;

G) Tulaga tutusa ma tutusa le lapopoa o fatu.E leai se lapo'a fatu e mafai ona sili atu nai lo le mea ua fa'amaonia.

H) Na'o le fa'atosina o le tuputupu a'e o saito Chromium carbide.

2.O le gaosiga uma, faʻapipiʻi e faʻaaogaina i Siamani, Suiselani, masini faʻaogaina;

3. Ua fautuaina e tipi i lalo ifo o le 60HRC;

Fa'aaliga

1. 100% taupou mea mata.

2. Eseese ituaiga o togi e availalbe fa'avae i luga ole talosaga a tagata faatau.

3. o loʻo i ai a matou faʻapolofesa faʻapolofesa laina gaosiga maualuga ma inspectiton meafaigaluega e faʻamautinoa ai oloa maualuga.

4. Sa'o eleele ma maualuga faiga fa'aiila

5. maualuga le ofuina o le tete'e, maualuga ma'a'a ma a'afiaga faigata

6. Fa'atekonolosi fa'apitoa , sa'o olo.

Lisi Vasega

| Vasega | ISO Code | Meatotino Fa'ainisinia Fa'aletino (≥) | Fa'atatauga | ||

| Malosi g/cm3 | Malosi(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Talafeagai mo le sa'o machining o u'amea lafo ma non-ferrous metala. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Talafeagai mo le sa'o machining ma semi-faauma o lafo uʻamea ma non-ferrous metals, faapea foi mo le faagasologa o le manganese sila ma tineia uamea. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | E fetaui lelei mo le faʻamaeʻaina ma le faʻaogaina o le uʻamea uʻamea ma le uʻamea mama, ma e mafai foi ona faʻaaogaina mo le faʻaogaina o le uʻamea ma le uʻamea maualalo. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | E talafeagai mo le fa'apipi'iina o vili ma'a ma'a fa'ata'amilomilo ma fa'a'a'ai fa'a'a'a'iga fasi ma'a. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | E fetaui lelei mo le fa'a'ofuina o ni nifo fa'a'u'u po'o ninifo mo masini vili ma'a mamafa e fa'aogaina ai ma'a malo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | E fetaui lelei mo suʻega faʻamalosi o pa uʻamea ma paipa uʻamea i lalo o faʻasalalauga maualuga. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | E talafeagai mo le faia o fa'ailoga fa'ailoga. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | E fetaui lelei mo le faia o le faʻailoga malulu ma le faʻapipiʻiina o le malulu mo pisinisi e pei o vaega masani, bearings, meafaigaluega, ma isi. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Talafeagai mo le sa'o machining ma semi-fa'amaina o u'amea uʻamea ma uʻamea lautele uʻamea. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | E fetaui lelei mo le faʻamaeʻaina o le uʻamea uʻamea ma le uʻamea maualalo. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | E fetaui lelei mo le faʻaogaina saʻo o uʻamea faʻavae, nickel-faʻavae maualuga-vevela alloys, ma uʻamea maualuga-malosi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | E fetaui lelei mo le tipiina o le sila ma le u'amea. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Talafeagai mo le sa'o machining ma semi-uma o le sila ma lafo uʻamea. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Talafeagai mo le sa'o machining ma semi-faauma o u'amea ma lafo uʻamea, ma fua fafaga feololo.YS25 ua fuafuaina faapitoa mo galuega viliina i luga o uʻamea ma lafo uʻamea. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Talafeagai mo mea mamafa-tiute tipi, maua ai taunuuga sili i le feliua'i talatala o castings ma eseese forgings uamea. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | E talafeagai mo le fa'apipi'iina o vili ma'a fa'a'a'ai fa'ata'amilo ma viliina i fa'ama'a ma'a'a. |

Fa'atonuga

Gaosiga Fa'agasologa

afifiina